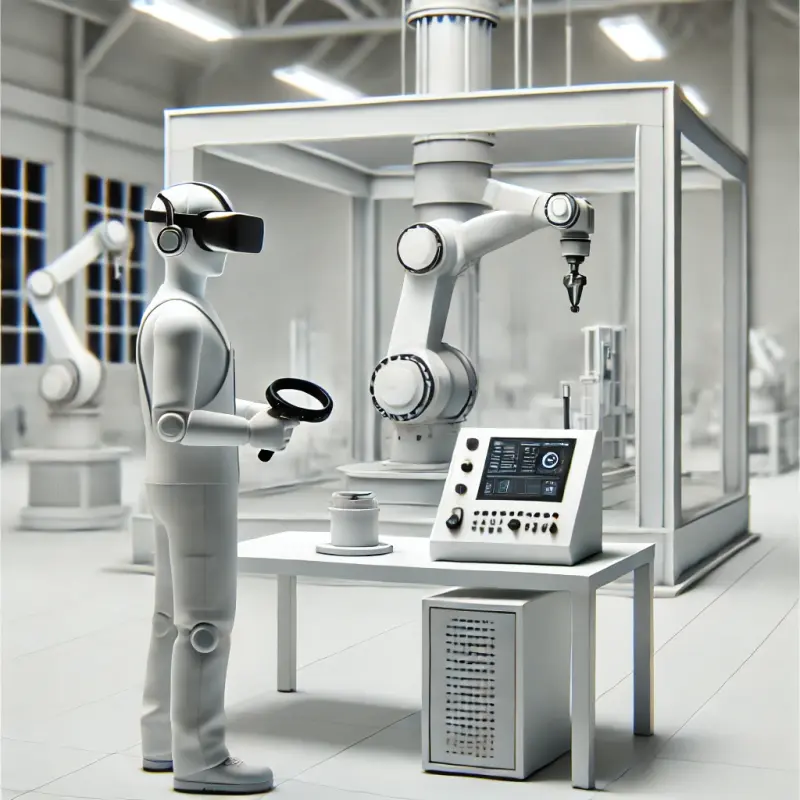

Virtual Simulators for Mastering Industrial Robotics Skills: How VR is Revolutionizing Manufacturing Training

Introduction

As industries continue to embrace automation, industrial robots are becoming an integral part of manufacturing and production lines. These robots, capable of performing complex and repetitive tasks, help streamline operations, improve efficiency, and reduce the risk of human error. However, mastering the operation of industrial robots requires specialized training, as their tasks involve a high level of precision and safety.

In recent years, Virtual Reality (VR) technology has emerged as a game-changer in the field of industrial robotics training. By providing a virtual environment where operators can simulate working with robots, VR helps users gain essential skills without the risks associated with real-world machine operation. This article explores how VR technology is used in industrial settings to train workers in handling industrial robots and how it benefits the manufacturing industry.

The Challenges of Training with Industrial Robots

Training workers to operate industrial robots traditionally involves hands-on learning with real machines. While this provides practical experience, it comes with several challenges:

- Cost of Training: Industrial robots can be expensive, and using them for training purposes may incur high costs, particularly if the robots are damaged during practice.

- Safety Concerns: Operating industrial robots requires strict safety protocols. Accidents and injuries are possible, particularly when training inexperienced operators.

- Limited Access: Some training centers may not have immediate access to industrial robots, limiting the number of individuals who can receive training at any given time.

- Time Constraints: The learning process for operating complex robots takes time, and hands-on training with real machines can be slow and inefficient.

These challenges have driven the demand for innovative training methods, which is where virtual reality comes in.

How VR Simulators Work in Robotics Training

Virtual reality technology allows users to immerse themselves in a computer-generated environment that simulates the physical world. For industrial robotics training, VR simulators replicate the entire robot operation process, allowing trainees to interact with virtual machines in real-time.

VR training simulators offer several key advantages:

-

Realistic Virtual Environments

VR training systems provide a fully immersive experience, simulating the interaction with robots in a safe virtual space. Trainees can manipulate robotic arms, perform complex tasks, and even experience operational failures—all without the risks associated with real-world training. -

Safe, Risk-Free Practice

Using VR simulators for training removes the safety concerns associated with operating actual industrial robots. Trainees can practice operating the robots, making mistakes and learning from them, without risking damage to expensive equipment or endangering themselves. -

Cost-Effective Training

VR-based training reduces the need for expensive physical robots. Multiple trainees can access the same virtual robot and practice the same tasks simultaneously, improving training efficiency without the overhead costs of real-world equipment. -

Instant Feedback and Performance Monitoring

VR simulators provide instant feedback to users based on their performance. If a trainee makes an error, the system can highlight what went wrong, enabling them to correct mistakes in real-time. This allows for more rapid learning and reinforces correct behavior. Additionally, VR systems can track the user’s performance, providing valuable data to instructors and allowing for personalized learning plans. -

Real-Time Simulations of Complex Scenarios

VR training systems can simulate complex, hazardous, or rare scenarios that would be difficult or unsafe to replicate in a real-world setting. Trainees can experience and learn how to handle situations like robot malfunctions, equipment failure, or emergency protocols, which might not occur frequently on a production line.

Applications of VR in Industrial Robotics Training

The use of VR simulators for training with industrial robots spans several critical areas in the manufacturing and automation industries:

-

Robot Operation and Programming

One of the primary uses of VR simulators in industrial robotics training is teaching workers how to operate and program robots. With VR, trainees can virtually interact with robots and practice the programming process. They can learn how to set up robots for various tasks, perform precise movements, and troubleshoot programming errors—all in a virtual environment that mimics real-world situations. -

Maintenance and Troubleshooting

Regular maintenance is essential for ensuring that industrial robots operate at peak efficiency. VR simulators provide an opportunity for technicians to practice diagnosing and repairing robots. Trainees can run simulations to identify faults, replace parts, and solve mechanical issues without the risk of damaging a real machine. -

Safety and Emergency Training

Training operators in safety procedures is crucial for avoiding accidents and injuries in industrial settings. VR allows trainees to practice emergency protocols, including stopping robots in case of malfunction, handling hazardous situations, and reacting to robotic arm failures. Such simulations provide an effective way to familiarize employees with safety practices without exposing them to real-world risks. -

Multi-Robot Systems

In advanced manufacturing setups, robots often work in tandem with each other, performing coordinated tasks. VR training allows users to interact with multiple robots in a synchronized environment, improving their ability to manage and optimize multi-robot operations. Trainees can practice how to control and communicate with multiple robots simultaneously, a skill crucial for modern production lines.

Benefits of VR Simulators for Robotics Training

-

Scalability

VR simulators can be used by multiple trainees at the same time, allowing for a scalable training solution. Instructors can have numerous students practice different aspects of robot operations concurrently, significantly reducing the time it takes to train a workforce. -

Flexibility and Accessibility

VR simulators can be accessed remotely, enabling employees from different locations to participate in training. This flexibility helps businesses offer training to a geographically dispersed workforce and provides employees with the opportunity to learn at their own pace, reducing downtime on the shop floor. -

Consistency in Training

VR ensures that all trainees receive consistent training, as the same simulations and exercises can be repeated multiple times. This consistency helps to ensure that every operator is equipped with the necessary skills and knowledge to handle robots efficiently and safely. -

Improved Retention

Studies have shown that immersive training experiences such as VR are more engaging and result in better knowledge retention compared to traditional methods. This means that trainees who use VR simulators are more likely to remember critical procedures and apply them successfully when operating industrial robots.

Conclusion

Virtual reality is transforming the way we approach industrial robotics training. By providing a safe, cost-effective, and immersive environment, VR simulators enable trainees to gain valuable hands-on experience without the risks and expenses associated with real-world training. As VR technology continues to evolve, it will play an increasingly important role in the development of skilled workers in the field of industrial robotics, helping industries around the world streamline operations, improve safety, and boost productivity.

As more industries adopt VR-based training solutions, the future of industrial robotics training looks promising. The combination of cutting-edge technology and immersive learning is shaping the next generation of robot operators, making workplaces safer and more efficient for everyone involved.

Articles

Opt-in for our notifications to stay updated with the latest and most captivating articles delivered to your email.